Browse Your Construction Company Efficiently with Top-Quality Aftermarket Construction Parts

Browse Your Construction Company Efficiently with Top-Quality Aftermarket Construction Parts

Blog Article

Boost Effectiveness With Aftermarket Components: a Guide for Heavy Equipment Owners

Advantages of Aftermarket Parts

Owners of hefty machinery can delight in countless benefits by choosing for aftermarket parts over original equipment producer (OEM) components. One of the main advantages is price savings. Aftermarket parts are normally a lot more budget friendly than OEM components, allowing machinery owners to minimize repair and maintenance costs without endangering on quality. Additionally, aftermarket parts commonly come with warranties, making certain that customers are protected in instance of any type of issues or flaws.

Because aftermarket makers specialize in producing certain elements, equipment proprietors have access to a broader array of choices to fit their demands. Aftermarket parts are understood for their quality and integrity, with many conference or surpassing OEM criteria.

Finally, picking aftermarket parts can also cause faster fixings and decreased downtime. With much easier accessibility and fast delivery choices, equipment owners can obtain their tools up and running once more swiftly, reducing disruptions to their procedures.

Choosing the Right Aftermarket Components

When thinking about aftermarket components for hefty equipment, it is important to prioritize compatibility and quality to guarantee optimal performance and longevity of the devices. Selecting the right aftermarket components can be a crucial decision for heavy machinery proprietors as it directly affects the effectiveness and reliability of their devices.

Secondly, high quality should never ever be jeopardized when picking aftermarket parts (aftermarket construction parts). Selecting high-grade elements makes sure longevity, integrity, and total performance of the machinery. It is recommended to source aftermarket components from reliable producers or vendors recognized for their quality standards

In addition, considering elements such as service warranties, client reviews, and compatibility with existing systems can even more assist in making the appropriate selection. By focusing on compatibility and top quality when picking aftermarket components, heavy machinery owners can improve the efficiency and long life of their tools.

Installment and Upkeep Tips

For reliable procedure and durability of hefty equipment, proper installment and normal maintenance are critical. When mounting aftermarket parts, make sure that you very carefully adhere to the manufacturer's guidelines to assure ideal efficiency. By focusing on more setup and upkeep procedures, you can make best use of the performance and lifespan of your heavy equipment, inevitably saving time and cash in the long run.

Cost-Effectiveness of Aftermarket Components

Correct installation and normal maintenance are fundamental aspects for hefty equipment owners intending to evaluate the cost-effectiveness of aftermarket parts for their tools. While initial tools producer (OEM) components are understood for their quality, aftermarket parts offer a more economical remedy without compromising performance. The cost-effectiveness of aftermarket parts comes to be obvious in different means. To start with, aftermarket parts are typically more economical upfront, allowing owners to accomplish cost savings on initial acquisition expenses. Additionally, these components frequently provide similar performance to OEM parts, ensuring that the machinery runs successfully without the demand for expensive substitutes. The availability of aftermarket components from a broad array of distributors promotes competition, leading to competitive pricing and further price savings for owners. By carefully examining the quality and compatibility of aftermarket components with their equipment, owners can strike an equilibrium in between cost-effectiveness this post and efficiency, inevitably taking full advantage of the efficiency and longevity of their hefty tools.

Optimizing Effectiveness With Aftermarket Upgrades

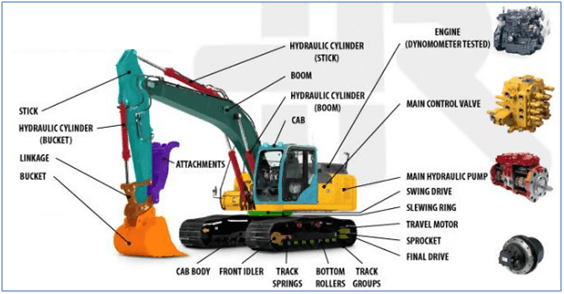

To improve operational performance and productivity, hefty equipment proprietors can effectively optimize effectiveness via strategic utilization of aftermarket upgrades. Aftermarket upgrades use the possibility to customize heavy machinery to specific operational needs, causing boosted performance and output. Upgrading parts such as engines, transmissions, hydraulic systems, and tracks can significantly improve the overall effectiveness of the equipment.

Regularly analyzing the performance of hefty machinery and determining areas where aftermarket upgrades can be advantageous is essential for making the most of efficiency. By purchasing quality aftermarket components and upgrades, equipment proprietors can attain higher levels of effectiveness, ultimately leading to cost financial savings and enhanced functional end results.

Final Thought

In final thought, aftermarket parts provide many advantages for heavy equipment proprietors, consisting of cost-effectiveness, raised effectiveness, and personalization alternatives. By picking the appropriate aftermarket parts, following appropriate installation and upkeep treatments, and maximizing upgrades, heavy equipment owners can enhance their tools's performance and durability. Investing in aftermarket parts can ultimately lead to improved productivity and lowered downtime, making it a rewarding consideration for owners wanting to optimize their equipment procedures.

Owners of heavy machinery can appreciate many benefits by deciding for aftermarket parts over original equipment producer (OEM) parts. Aftermarket components are commonly a lot more affordable than OEM components, enabling equipment proprietors to minimize upkeep and fixing prices without jeopardizing on quality. By meticulously evaluating the high quality and compatibility of aftermarket parts with their machinery, proprietors can strike a balance in between cost-effectiveness and performance, inevitably taking full this content advantage of the performance and durability of their heavy tools.

In verdict, aftermarket parts supply countless benefits for heavy equipment proprietors, including cost-effectiveness, raised performance, and modification options. By picking the ideal aftermarket components, adhering to appropriate installment and upkeep treatments, and optimizing upgrades, heavy machinery proprietors can improve their tools's performance and longevity.

Report this page